RxD® aqueous inkjet pigment dispersions

High stability, high purity pigment dispersions for inkjet ink formulation.

Simplify the challenges of ink formulation

Fujifilm’s high quality RxD aqueous pigment dispersions enable the creation of high performance inkjet inks for a wide range of applications, including packaging, textile, commercial and industrial printing.

They are engineered with Fujifilm’s proprietary dispersant technology for exceptional stability, enabling excellent flexibility in the range of components that can be used in the ink formulation. In combination with its ultra high purity, RxD enables you to create inks with the most demanding specifications in jetting, image quality and application performance.

Working with a highly stable dispersion gives you the potential to achieve the optimal formulation quickly and cost-effectively, so streamlining ink development.

Introducing RxD aqueous pigment dispersions

The pigment dispersion is the most important component in an aqueous inkjet ink. That’s why we created our own dispersion technology, and now we are making this technology accessible to you.

Designed for high performance aqueous inkjet inks

Formulation flexibility

Expand the range of solvents and surfactants you can use in your ink formulation.

Optimal jetting

Design reliable inks for a wide range of printheads.

Consistent to specification

Rely on RxD in your formulation. Every batch meets tight specifications.

Flexibility in your ink formulation

RxD dispersions have all the properties you need to create robust inks for many applications, including the most demanding applications of the future.

Exceptional stability enables use of strong co-solvents, and aggressive surfactants to achieve high image quality and ink functionality. High pigment concentration gives latitude to achieve the optimum formulation. Compatibility with soluble and emulsive binders and latexes that create endurance.

Optimal jetting performance

Ultra high purity dispersions enable you to create inks for the most demanding inkjet systems, minimizing risk of printer downtime due to nozzle blockages or printhead damage.

Narrow particle size distribution and low oversized particle count makes them particularly suitable for use in inks for thin-film printheads. Elimination of microbial activity reduces risk of nozzle deviation or blockage.

Consistent specifications you can rely on

The inks you manufacture must be consistent for reliable performance in the field. The quality of your raw materials is critical.

Precision manufacturing processes and quality control ensure our dispersions consistently meet their specification. Polymer uniformity between colors ensures consistent formulations, simplifying ink design.

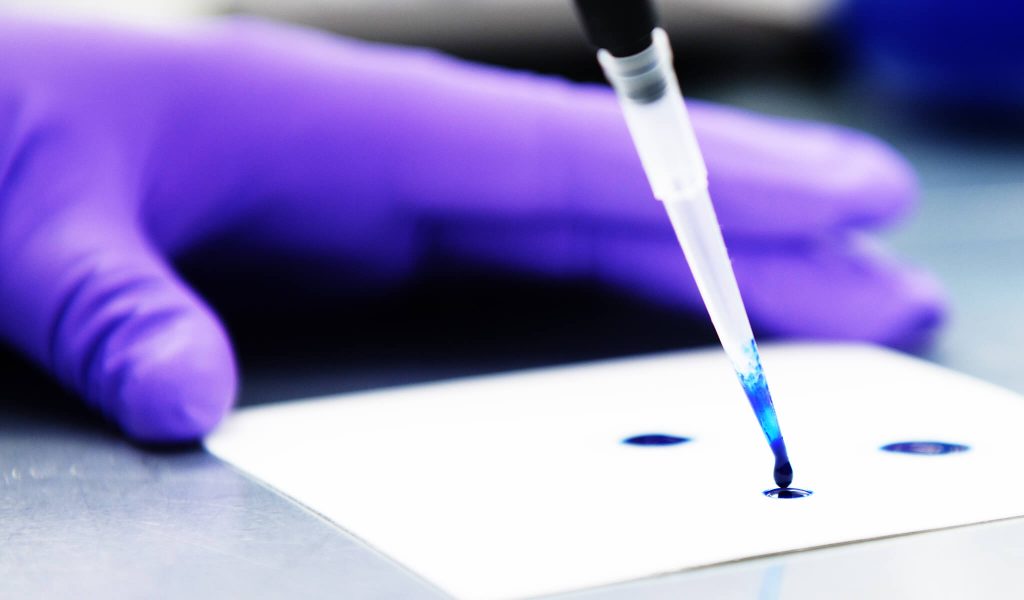

Proven stability

Some dispersions break down with more challenging co-solvents. The exceptional stability of RxD enables it to remain stable with a wide range of solvents.

In the below photographs, competitor dispersions show clear desorption after the solvent was added, in contrast to the stability of the RxD dispersion.

Tests completed with 25% w/w dispersion added to 75% w/w 2-Butoxyethanol.

Tests completed with 25% w/w dispersion added to 75% w/w 2-Butoxyethanol.

Engineered for exceptional stability

RxD: Reactive dispersant cross-linking technology. Fujifilm RxD aqueous pigment dispersions use a precision stabilization process that locks the pigment particles in a robust cage of cross-linked polymer.

Learn more

RxD: frequently asked questions

Read hereRxD: The versatile pigment dispersion for a wide range of inkjet applications

Packaging

Create inks for applications on fibre-based and flexible packaging materials. RxD dispersion products designed for packaging are suitable for indirect food contact applications.

Commercial

Create inks for commercial, document and imprinting applications where productivity, image quality and color accuracy are critical factors for success.

Textile

Create inks for a wide range of textile materials. Formulate high performance inks with excellent crock-fastness, color-fastness, and wash-fastness. RxD is suitable for inks that meet GOTS and OEKO-TEX standards.

Industrial

Create inks for a wide variety of industrial applications, where color, print performance and end-product durability are key requirements, as well as compatibility with primers and coatings.

Learn more

Related articles